Aalmir Plastic Industries realized early on that down gauging of the film resulted in significant cost savings for customers and has been offering down gauging optimization to customers as standard.

The key to cost-efficient down-gauging is to match the same mechanical properties of the film at a lower thickness. This requires an in-depth analysis of the customer’s specific applications and testing of various extrusion and formulations process that can allow this. Based on Aalmir Plastic Industries current experience, it is possible to easily down gauge most legacy LDPE and LLDPE applications by 15-35%.

To achieve same property at a lower thickness would require the use of latest extrusion machinery and latest materials. It’s important to carry our full viability or process and materials since some material can only yield performance benefits if run with special extrusion methods.

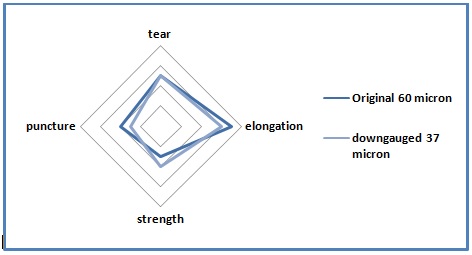

An example of Aalmir Plastic Industries down gauged film can be seen below;

Application: Collection bag for soiled linen

Max weight required: 14 kg

Original Formulation: LDPE/LLDPE blend

Thickness: 60 micron

Bag size: 110X 80cm ( 97 grams)

Yearly consumption: 370,000 bags ( 35,800 kgs)

After extensive testing of bag and application, Aalmir Plastic Industries was able to conclude that the bag required to be stiffer (strength) and that requirement of puncture resistance was not needed to the extent since content did not have sharp objects. This allowed for the possibility of selecting high stiffness materials in inner layers to provide these properties and, therefore, being able to reduce customer’s thickness from 60 to 37 microns.

Even though the new material required the use of slightly more expensive polymers, the cost saving was still substantial enough to warrant a change. The cost saving achieved for this application was 38% lower thickness which achieved a total cost saving of 25% on customers spend on this item.

Take advantage of Aalmir Plastic Industries expert film development capabilities and testing labs to help down gauge your film for optimum yield performance.