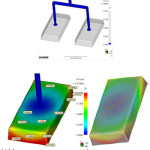

Once the design has been finalized and appropriate material has been selected, the final stage of pre-production evaluation is conducted. Depending on the final requirements, the designs may go through a number of virtual computers aided tests including but not limited to material flow analysis, finite element analysis and 3d simulation testing. If all virtual test are not enough and an actual prototype is required, the approved design can be transformed into a prototype via either 3d printing (rapid prototyping), fabricating, CNC tooling or a combination of all three.

Once the design has been finalized and appropriate material has been selected, the final stage of pre-production evaluation is conducted. Depending on the final requirements, the designs may go through a number of virtual computers aided tests including but not limited to material flow analysis, finite element analysis and 3d simulation testing. If all virtual test are not enough and an actual prototype is required, the approved design can be transformed into a prototype via either 3d printing (rapid prototyping), fabricating, CNC tooling or a combination of all three.

In conjunction, the planning stage and timeline of the project will be also be drafted during this stage. Timelines will generally include the different phases included in the manufacturing of the mould and how long each step of the process will take.

In conjunction, the planning stage and timeline of the project will be also be drafted during this stage. Timelines will generally include the different phases included in the manufacturing of the mould and how long each step of the process will take.

Stage 3- Design evaluationAlmirDxb8532017-02-18T11:57:08+04:00